The Wavemaker® G4mini system is designed to quickly inspect 100% of the volume of long lengths of pipelines from one position. The Wavemaker® G4mini offers…

Shop

Showing 1–16 of 40 results

-

Wavemaker® G4mini

-

WavePro4 Software

The WavePro4TM guided wave analysis software runs on a Windows® based operating system and interfaces with the Wavemaker® G4 and G4mini instrument. The software assists…

-

Compact Rings

The Compact® rings are designed to be lightweight and low profile while still providing excellent results. This makes them the default solution for most applications.…

-

EFC Inflatable Rings

These transducer rings are designed to provide effective inspection capability, particularly for larger diameter pipes. Pneumatic pressure is used to press transducers modules (which are…

-

Claw Transducers

The Claw System is a breakthrough probe development designed for efficient boiler tube inspection, especially in restricted access scenarios. Unlike traditional methods such as conventional…

-

EFC Solid Rings

The solid transducer rings are typically used for standard screening of pipes with nominal size between 2 and 8 inches in diameter. The rings are…

-

gPIMS® Field Control Unit

The gPIMS® Field Control Unit (FCU) autonomously collects and stores data from a connected gPIMS® sensor. Our most popular wireless versions transmit the data directly…

-

Monitoring Studio

The Monitoring Studio is a user friendly way to view the data generated by our monitoring systems, analyse it for information such as corrosion rates,…

-

gPIMS® Sensor Rings

The gPIMS® sensor rings are an environmentally robust range of sensors developed to be easily bonded onto the pipe, sealed and then left in place.…

-

GUL i-Button Reader

£98.00GUL i-Button Reader. Compatible with GUL i-Button. Price includes USB converter. Price includes shipping.

-

GUL i-Button Replacement

£225.00GUL i-Button Replacement. The i-Button is required to operate GUL equipment; the GUL inspector qualification and Certification expiry date are stored on the i-button.…

-

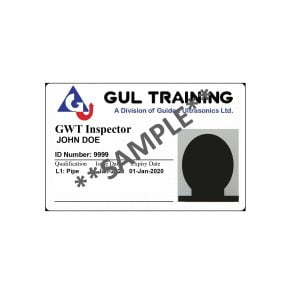

GUL Inspector Card Reissue

£118.00Operator Card Reissue. The GUL operator card displays a photograph, the qualification and Certification expiry date of the operator/inspector. Price includes shipping.

-

GULT Certificate Late Renewal

£820.00GULT Certificate Renewal for GUL inspectors applying after the expiry of their certificate validity period, but within the period of 12 months following the…

-

GULT Certificate Reissue

£118.00GULT Certificate Reissue. The GULT Certificate attests the GUL Inspector’s level of proficiency in a qualifying field and the period of validity. Price includes…

-

GULT Level 3 Certificate Renewal

£540.00GULT Certificate Renewal for GUL Level 3 inspectors applying within the certificate validity period. Price includes processing and admin fees. Price includes shipping of…

-

GULT Certificate Renewal

£450.00GULT Certificate Renewal for GUL inspectors applying within the certificate validity period. Price includes processing and admin fees. Price includes shipping of new Certificate…