Wavemaker® G5

The next generation of Guided Wave Technology.

Achieve precision testing effortlessly.

This instrument is the latest generation of renowned GUL Wavemaker® Pipe Screening System, developed specifically for advanced guided wave testing (GWT) of pipelines. Built on over two decades of field experience, the G5 introduces key enhancements in hardware performance, user interaction, and inspection workflow.

As asset owners seek faster, more efficient methods that minimise operational disruption, the G5 delivers improvements in data quality while reducing operator workload. The system combines a compact, ruggedised design with a powerful onboard computer and streamlined software environment—supporting efficient inspections whether in the hands of experienced users or newer technicians.

A Platform Designed for the Field

Every aspect of the Wavemaker® G5 has been purposefully reimagined to meet the rigorous demands of field‑based inspections. It’s compact enclosure, designed to IP54, and glove-compatible, ultra-bright toughened touchscreen ensure dependable operation across a range of challenging environments—including offshore, upstream, midstream, and downstream sectors, as well as buried and insulated pipelines. Dual hot-swappable batteries further support uninterrupted operation, enabling extended use without the need to pause for charging.

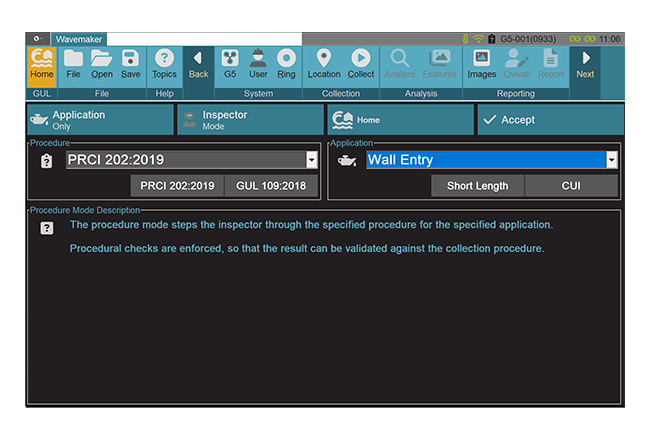

At the core of the system lies an integrated computing platform that streamlines the entire data acquisition‑to‑reporting workflow. The embedded WaveProX™ software enables direct instrument control, while compatibility with WaveProV™ on an external laptop offers added flexibility. Procedure-driven collection routines, combined with intelligent feature recognition tools, reduce inspection variability and support fast, confident decision‑making in the field.

Empowering the Front Line

The Wavemaker® G5 is designed with the inspector in mind—supporting confidence at every level of experience. For newer technicians, procedure‑based collection minimises the risk of user error and guides consistent, compliant operation from the outset. Built‑in prompts and software-assisted interpretation help standardise inspections, allowing users to focus on collecting quality data rather than managing system complexity.

For experienced inspectors and Level 2s, the G5 enhances oversight and control. Progress and performance can be monitored in real time via optional remote access, ensuring team members remain aligned with established procedures. The streamlined workflow also reduces cognitive load, enabling senior personnel to focus on decision‑making, supervision, and troubleshooting when it matters most.

Compatible. Intelligent. Efficient.

The G5 is designed to integrate effortlessly into existing workflows, supporting all GUL Screening Rings and non‑ATEX gPIMS® Monitoring Sensors for full backward compatibility. Whether upgrading from a previous generation or expanding your current setup, it offers future‑ready capabilities without compromising proven infrastructure.

A newly developed instrument‑to‑sensor cable ensures compatibility with existing rings, allowing users to benefit from the latest platform improvements in performance, reliability, and ease of use.

Ring configuration, size, and serial number are detected automatically, reducing setup time and eliminating manual entry. For Compact™, HD, and HT rings, the system also detects orientation and reads pressure and temperature sensors—enabling intelligent communication between hardware and software.

A particular efficiency is the ability to simultaneously collect standard and high‑frequency screening data when using Compact™ rings populated with TRIO modules. This not only saves time in the field but also streamlines analysis and reporting by consolidating results within a single data file.

Why Choose the G5?

Smarter Technology, Better Results

- Configuration that extends range in buried pipe

- Optimised collections for better defect detection

- Software‑assisted feature recognition automation

- Unmatched reliability in challenging environments

Maximise Your Team’s Potential

- Procedure‑based collection empowers L1 inspectors

- Simplified analysis workflows for accuracy

- Streamlined reporting for efficiency

- Remote assistance for instant troubleshooting

Always Ready – Work Without Delays

- On‑board touchscreen computer for direct control

- Option to connect to external laptop for flexibility

- Hot‑swappable batteries for uninterrupted operation

- Remote calibration to stay operational

Trusted by Professionals, Backed by Experts

- Industry‑leading training & qualification by experts

- Unrivalled support – expertise that sets us apart

- GUL patented technology that redefines standards

- Subscription‑free software – no hidden costs