Description

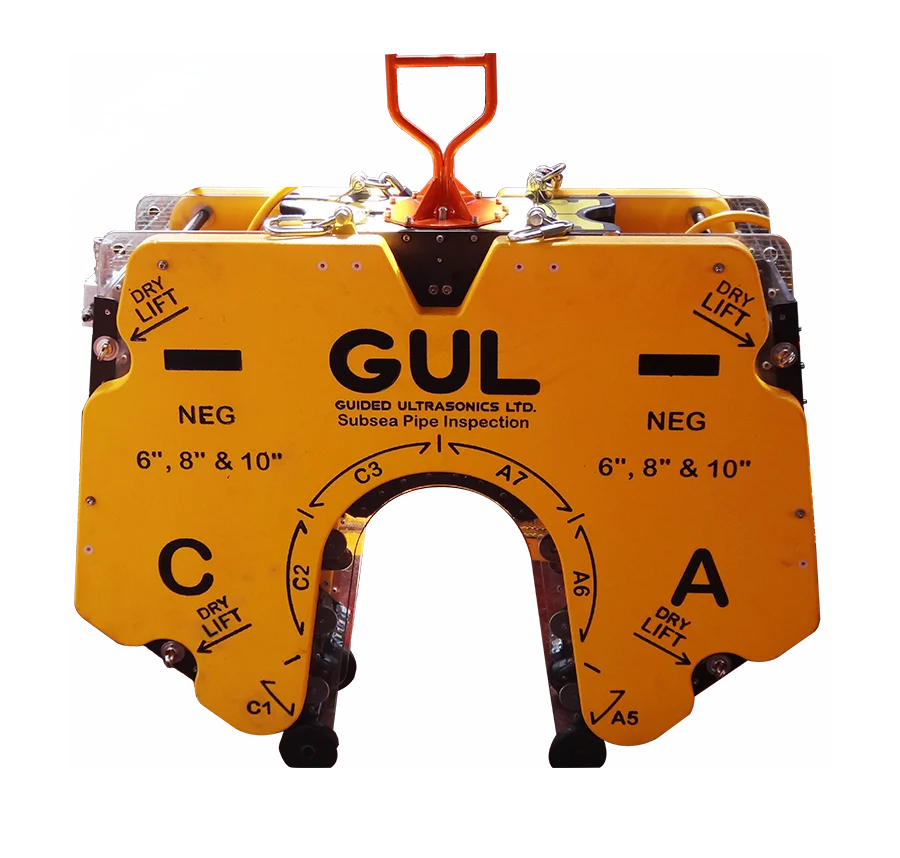

ROV Deployed

A Subsea G4mini is mounted on the ROV. A hydraulic connection is used for opening and closing the ring. The test is carried out from the ROV control room.

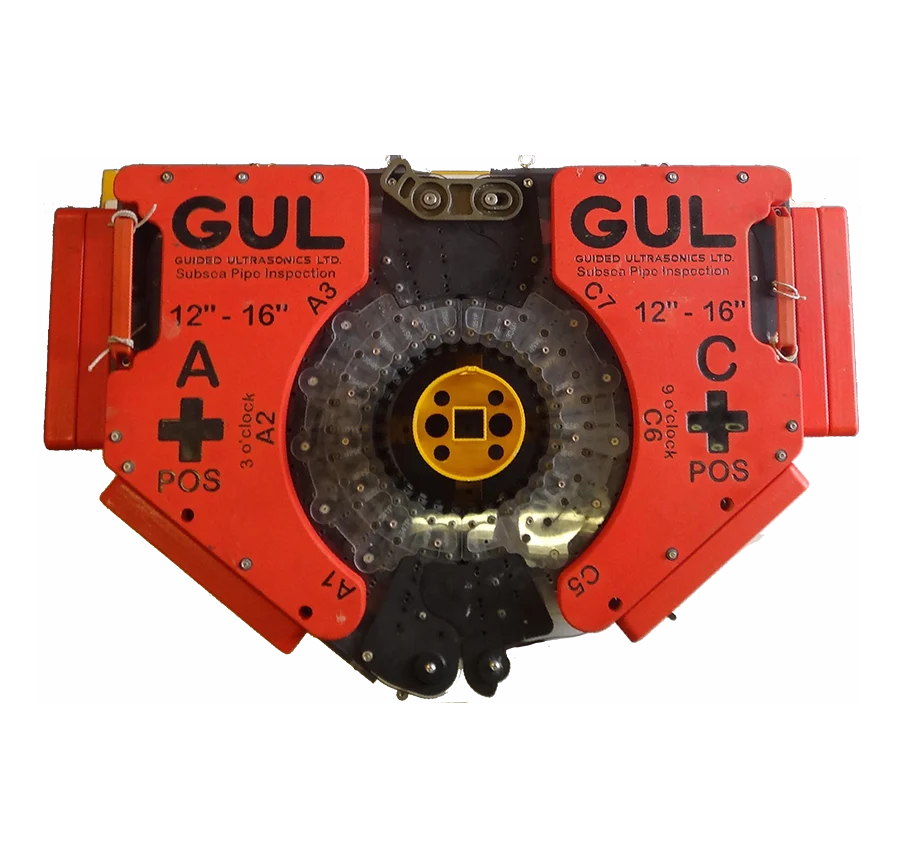

Diver Deployed

The test is controlled via an umbilical from a topside interface box to the Wavemaker instrument. The rings are installed on a clean section of pipe by 1 or 2 divers using a mechanical clamping mechanism.

Specifications ROV

Number of Channels

12

Nominal Pipe Size (NPS)

6” to 10” (DN 150 to 250)

Operating Depth

Down to 3,000 msw

Transduction System Compatibility

Wavemaker® Subsea G4mini only

Specifications Driver

Number of Channels

12

Nominal Pipe Size (NPS)

4” to 26” (DN 100 to 650)

Operating Depth

Any diver depth

Transduction System Compatibility

Wavemaker® G4mini ( < 50m depth) Subsea G4mini ( > 50m depth)