Studios

-

Support

-

Contact us

-

Products

Studios

In ideal circumstances, the test range can be more than 200 meters (650 feet) in each direction. However, the actual inspection range varies depending on several factors including:

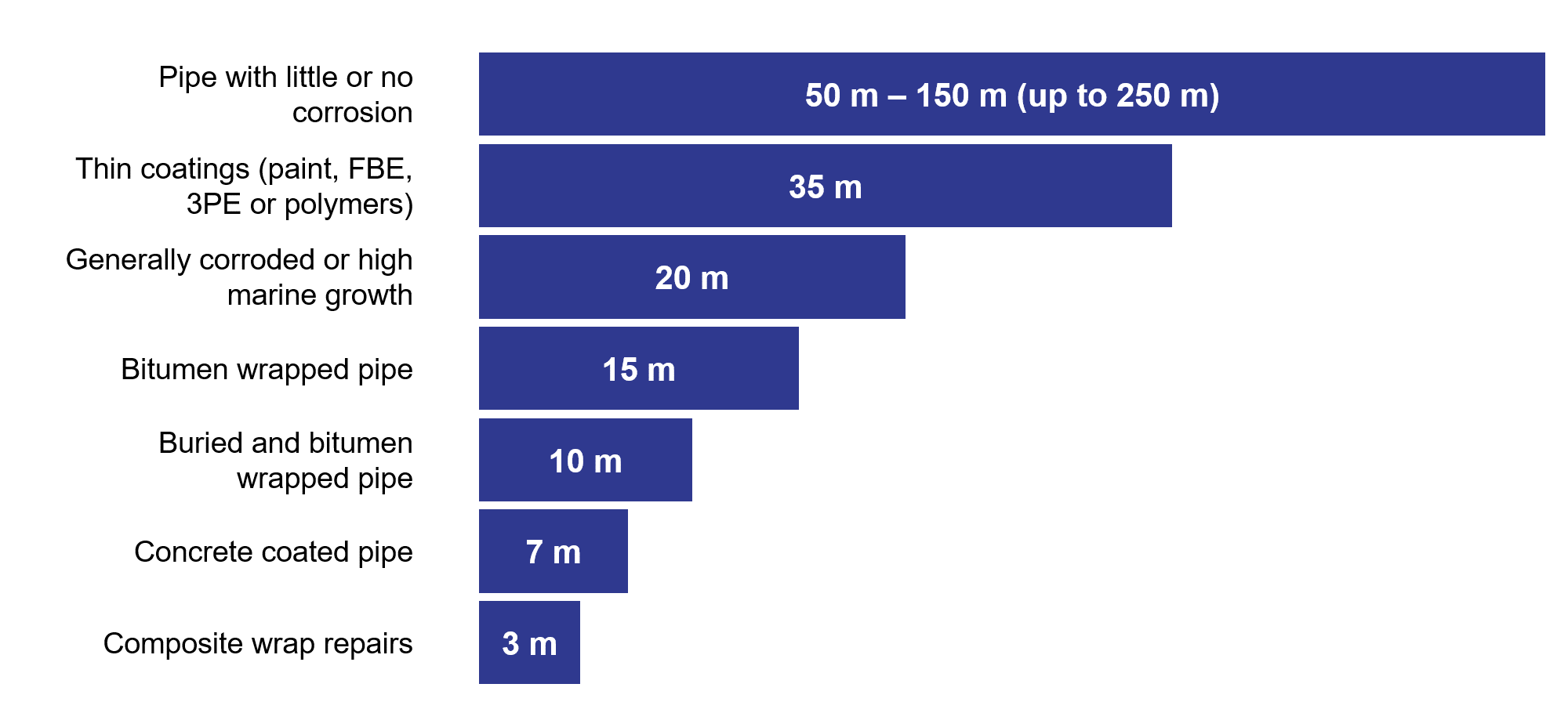

This figure provides a guide to the typical and average inspection range for GUL Screening:

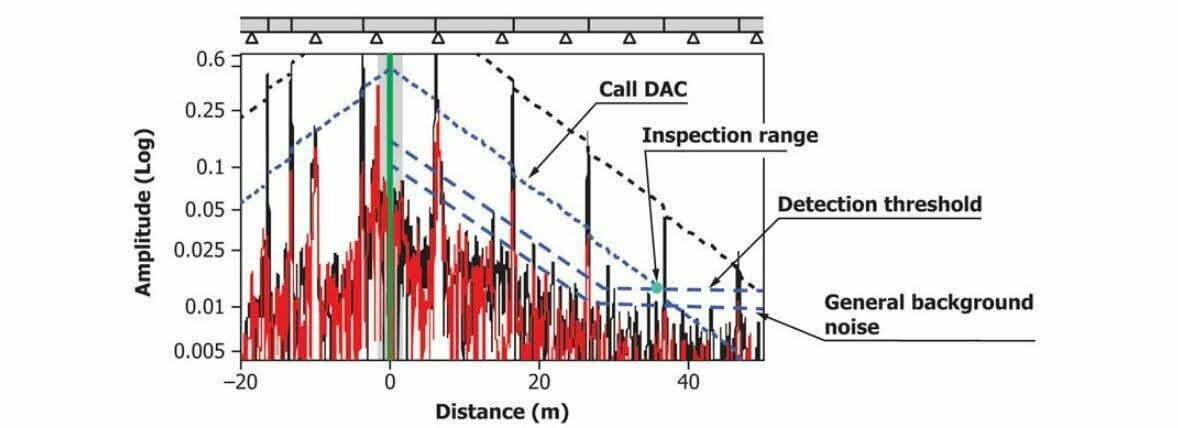

As part of analyzing the result, an inspector will mark the actual achieved inspection range for that test for the declared call level. If the test is not limited by certain pipe features such as flanges or elbows, this is done by determining by the intersection of the Call and Detection Threshold (DT), which is typically defined as 6 dB above the noise level.

By using this method, the known range for a known call level can be verified for each test result.