Studios

-

Support

-

Contact us

-

Products

Studios

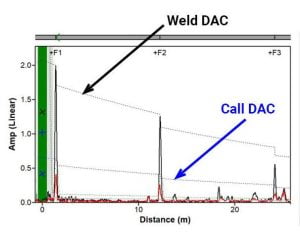

The DAC curves provide a quantitative link (or calibration curve) between the signal amplitude and cross-sectional area change (CSC) within the pipe. so that we can ultimately quantify the extent of the damages in terms of pipe CSC. An accurate DAC curve is required to classify the severity of defects in pipes.

The figure on this page shows an A-scan with the Weld and Call DACs labelled. In most inspections, the Weld DAC is established by using either weld size parameters or via the Absolute Calibration method. This results in a calibrated Call DAC, which can be used to estimate defect severity and determine end of inspection test range.

The Call DAC is the threshold level that is used to determine the defect severity if found. Typically, it is set between 1% and 6% CSC according to the sensitivity requirement of the inspection.