Studios

-

Support

-

Contact us

-

Products

-

0

Cart

Studios

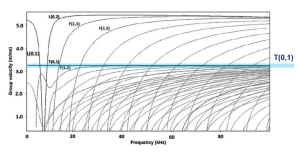

GUL Screening uses the fundamental torsional wave, known as T(0,1), for several main reasons.

These advantages help to reduce inspection complexity, give higher signal-to-noise ratio (SNR) and a higher range of inspection applications.

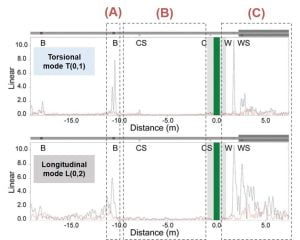

Using the Longitudinal wave (L(0,2)) can introduce a bigger error due to varying speeds, poorer signal to noise ratio (SNR) due to an additional mode and inability to inspect pipes with liquid contents. The figure below shows a comparison in inspection results between the T(0,1) and L(0,2) guided wave modes.

(A) T(0,1) has a lower coherent noise at the bend which increases the probability of detection (POD) of erosion; L(0,2) shows high coherent noise at the bend. (B) T(0,1) has a better signal-to-noise ratio (SNR) which increases the POD of smaller corrosion patches; L(0,2) has poorer SNR. (C) T(0,1) gives a better SNR after the welded support for a higher POD of corrosion patches after the welded support; L(0,2) has significantly poorer SNR which reduces inspection range and lower the POD of corrosion.

The top animation shows the Torsional T(0,1) mode in water filled pipe. Energy does not leak into the liquid content since all of the surface motion is shearing that does not couple.

The other animation shows the Longitudinal L(0,2) mode in water filled pipe. There is energy leakage into the liquid content since there is out of plane motion at the pipe surface. This energy leakage reduces the range and decreases the SNR because the laves travel through the liquid and back into the pipe.

Although GUL Screening uses the T(0,1) for almost all of inspection applications, the system is still capable of using the L(0,2) mode for development purposes and this functionality is available to inspectors in the field.

Two areas where the L(0,2) has a theoretical advantage over the T(0,1) are:

However, we find in practice that even in these situations, the T(0,1) results out perform the longitudinal ones.

Please see this academic article for more information.